The Nicholson Roofbox® is a weatherproofing solution for building services, and an alternative to Jones and Woolman UK’s own weatherproofing system for service risers. The two approaches to weatherproofing building services are very different. The Nicholson Roofbox® showcases an off-the-shelf solution, while Jones and Woolman UK provides a bespoke approach to preventing water ingress.

As an off-the-shelf product, the Nicholson Roofbox® undoubtedly represents a convenient solution. However, that convenience must be balanced against whether it is the right solution for an individual project. Does the Roofbox® align with the building’s architectural vision? And is it better for the project overall to engage a weatherproofing specialist earlier in the design process

What is the Nicholson Roofbox®?

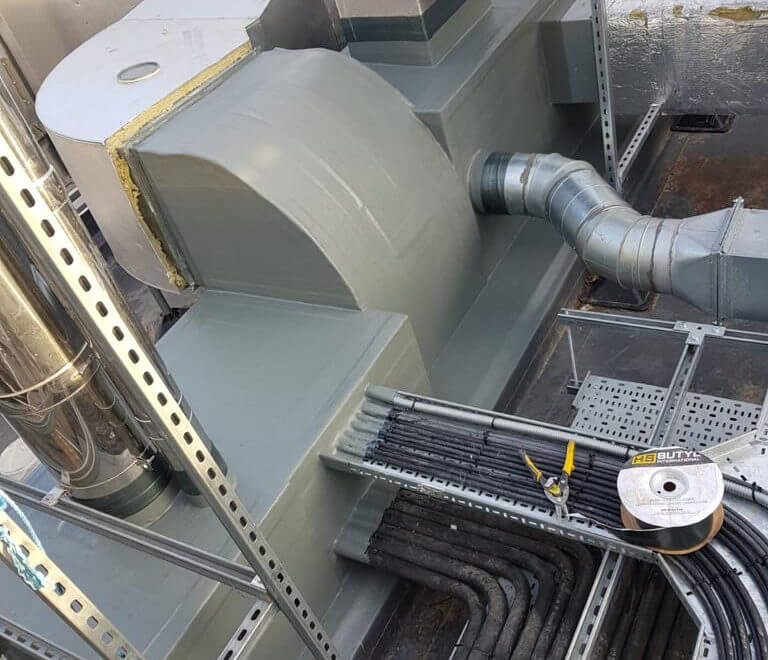

The Nicholson Roofbox® is a factory-made cabinet, available in different sizes and specifications to accommodate service penetrations. The various models of Roofbox® can accommodate multiple pipework and duct runs.

Instead of weatherproofing multiple service penetrations, only the Roofbox® itself needs weatherproofing. Once installed, it allows access for running and inspecting the services within, making for a convenient solution that carries little risk of water ingress.

What is Jones and Woolman UK’s weatherproofing system?

At Jones and Woolman UK, we create safe and reliable covers and seals of any shape or size, including clusters of multiple services. We insulate and weather service risers at curb level, directly to the services. Our solution is seamless, doesn’t restrict the direction of the services, and removes the requirement for ‘dog kennel’ style detailing.

Standard weatherproofing details are available on our website, which can be employed at any stage of a project to help achieve the right level of integration between building envelope and services. And we are often called on in an emergency, to address a problem that has arisen on site.

We can provide in-situ weathering for service risers in existing buildings. However, an even better way is for us to be involved from the early stages of projects. We work with clients to develop solutions for new build projects and can provide a vital connection between different members of the project team.

What disadvantages are there with the Nicholson Roofbox®?

Where a system like Jones and Woolman UK’s looks to minimise the impact of service penetrations on the performance of the building envelope, the same may not necessarily be said of the Roofbox®.

Roof cabinets, like the Roofbox®, are marketed on the basis that the building services design is not usually known in the early stages of a project. The ability to accommodate more services than might be anticipated is therefore promoted as an advantage.

However, the larger the cabinet, the larger the penetration through the building envelope, creating a significant thermal bridge. Cabinets are insulated, but compared to modern roof U-values they are still a comparative weak point in the thermal envelope.

For building envelope efficiency, thermal bridges should be kept to a minimum rather than being made bigger ‘just in case’. But if you don’t make a roof cabinet bigger ‘just in case’ then you are left with a restrictive solution that doesn’t allow services to be added after installation. Jones and Woolman UK’s service has no restriction on services coming through the plant deck, and services can even be added after installation.

And as an off-the-shelf solution, the Roofbox® is not designed with the aesthetics of the specific project in mind. They are, of course, very well finished, but designed to be a universal solution to an issue that is unique on each building. They are purchased and installed to perform a function; not to align with the architect’s vision for the finished building.

This leads into another drawback that applies to roof cabinets generally, as Matthew Jones, Sales Director at Jones and Woolman UK explains: “Roof boxes and cabinets are often installed and weatherproofed crudely, so the finish is not as good as it could be. It also means the sealants and fixings are more prone to water ingress and associated issues, which is precisely what the roof box is supposed to guard against.”

Using a design and build service compared to a Nicholson Roofbox®

Improvising solutions on site, or relying on off-the-shelf solutions, can spoil the architectural vision of a building and have a negative impact on the building envelope performance.

By contrast, Jones and Woolman UK can be part of the design team. Starting at the concept stage, our early involvement enables us to design and manufacture a high-performance weatherproofing system that works with the building.

Our cold-applied liquid GRP system can accommodate any type of roof system, can be applied to horizontal or vertical penetrations, and it is backed by a 25-year warranty to reduce risk and offer greater peace of mind.

Early involvement also means we can offer a dependable schedule of service and a high degree of installation flexibility that works with the sequencing of the project, helping to deliver on time and to budget. The principal contractor therefore enjoys the confidence of knowing their programme schedule is less likely to be disrupted.

Cost may also be something else worth considering. Whilst it could be assumed that purchasing an off-the-shelf solution would be cheaper than a more bespoke weatherproofing service, this may not be the case. Once you factor in the purchase of the product, the delivery and installation of the roof box, the overall cost is very comparable to a bespoke solution such as J&W’s. Additionally, roof boxes usually come with a five-year warranty as standard whereas a Jones and Woolman UK solution is backed by a robust 25-year warranty which offers significant benefits and highlights the confidence a bespoke solution can afford a project.

To find out more about Jones and Woolman UK’s weathering system for service penetrations, contact us about how we can help on your next project.